MARK HOPE, COO AND GM, EAVX: Reflecting back, the mission of 2021 was to evaluate the industry and see where EAVX fit in that sphere. We considered the major players of the industry and where we need to be from a body standpoint. We also evaluated the industry challenges that presented themselves last year and in 2020. These challenges are well known, with the supply chain presenting the biggest challenge, leading to chassis shortages among other shortages.

Then on the electrification side, it was, again, determining the biggest players in the industry and figuring out how we can collaborate with each other. Our EAVX team spoke with and met with everyone in the electric vehicle space. We identified potential collaborations, one being our collaboration with Zeus Electric Chassis, Inc., which Modern WorkTruck Solutions has covered, to integrate JBPCO commercial bodies, utility bodies, and cargo management systems with the Zeus Power Platform. We also focused on specific body types, such as refrigeration, walk-in van, and service bodies with different manufacturers like Morgan Olson, Morgan Truck Body, and Reading Truck.

HOPE: From an industry standpoint, I expect to see the industry to continue working through supply chain issues this year. However, I do expect supply to catch up with demand and for us to eventually come out of these shortages. The backlog is still high for components and vehicles. And not only is the backlog for vehicles high, but demand is still rising. But once we do come away from those shortages and demand is met, I expect there to be a pickup in the industry marketplace, and pressure on businesses to shift to “green” operations will bring on even more growth. This growth includes different chassis platforms, different engine components, and more to accommodate alternative fuels and reduce emissions and the impact on the environment.

As far as EAVX is concerned, expect to see new product introductions in 2022.

HOPE: EAVX as a business unit speaks to JBPCO’s commitment in developing the next generation of truck bodies through the formation of the unit and the investment JBPCO has put into EAVX. With EAVX, JBPCO has centralized the focus of the next generation into one business unit.

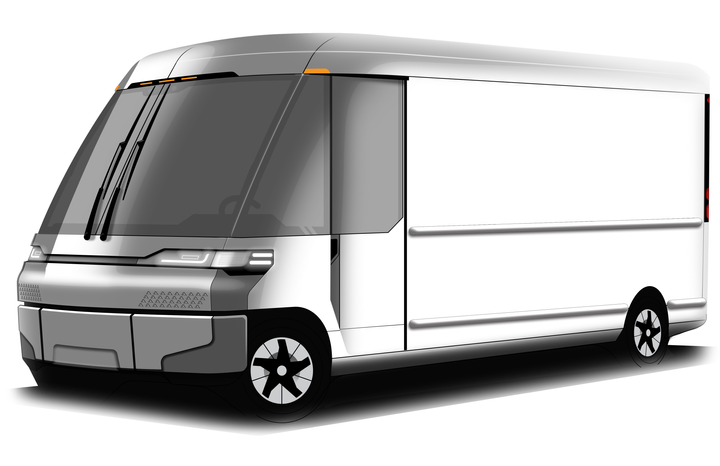

HOPE: The intent behind EAVX was to establish a tighter integration between the body and the chassis. Traditionally, there were two different streams of operations: those that work exclusively with the truck body, and those that work exclusively with the chassis. EAVX’s goal is to bridge the gap between the two and collaborate with different chassis manufacturers to enhance the electric value to the customer. You can put a truck body on any battery, but if we at EAVX can figure out ways to provide completed solutions for the end user that makes the work safer, more efficient, and more ethical, that’s where you find the value.

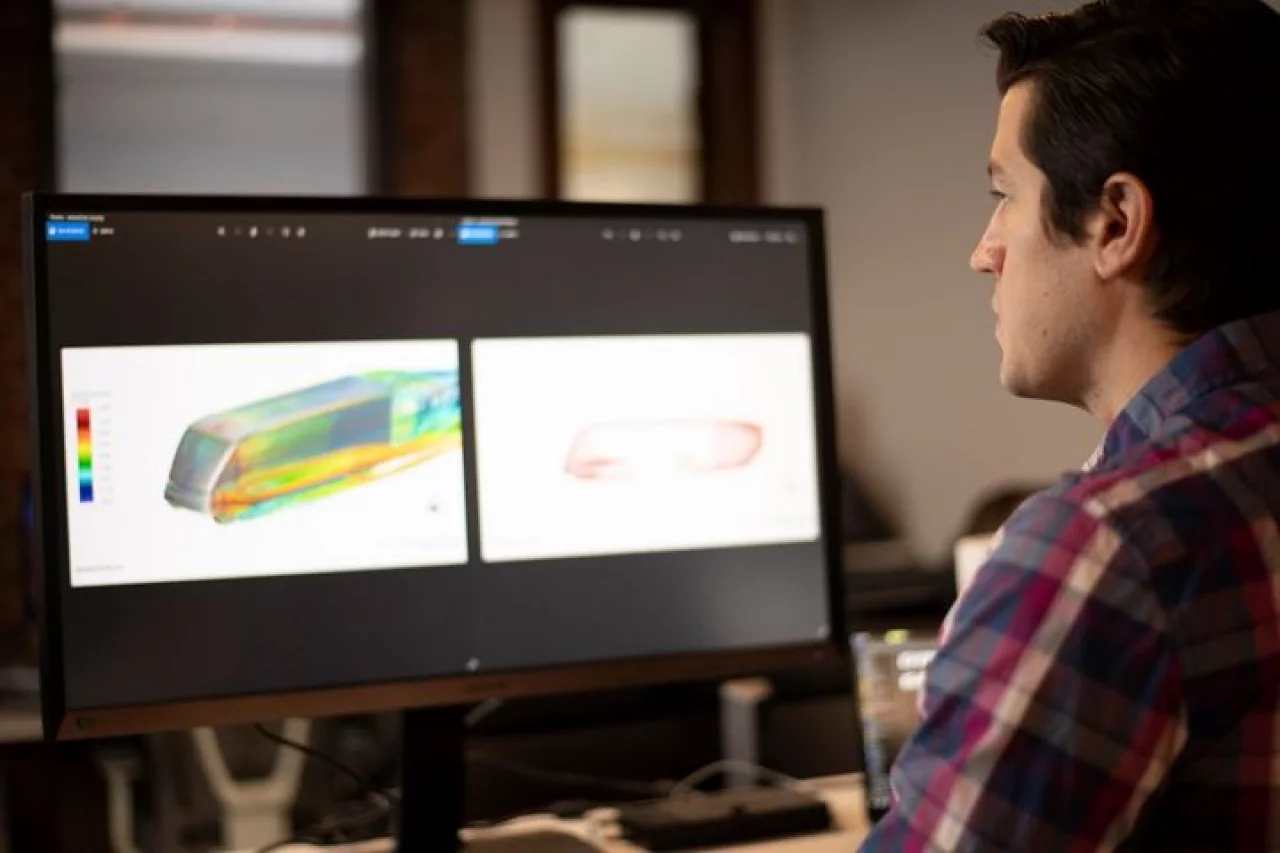

EAVX is all about finding creative and innovative ways to provide value to the end user. And we can accomplish this through body design, weight structure analyses, and technology integration.

HOPE: It’s important to understand that EAVX will not produce work truck bodies. The bodies developed through EAVX partnerships will be bodies from brands that fleet owners already know, such as Reading, Morgan, and others. EAVX will provide the ideation and integration. Some of these bodies will be available to customers sooner than others, because our focus for this year continues to be establishing relationships and building partnerships with manufacturers in the industry.

This year, we also aim to establish integrations with a new chassis platform (such as an electric chassis) and a current truck body that fleet owners use today. The chassis will be the variable in the beginning, but eventually EAVX will aim to revolutionize the body.

HOPE: With an electric chassis, the powertrain is replaced with a battery, which provides significantly much more room but also weighs more than a conventional powertrain. EAVX aims to explore how we can optimize the body with the new electric chassis. We want to explore and envision what the body can do—or maybe what we need to do to make it more efficient. For example, on a service body, we might find that it makes more sense to reduce its weight to balance out the weight from the addition of the battery.

The reason JB Poindexter and Co. formed EAVX was because the group is the largest commercial service body provider in North America with each business unit focused on meeting the demands of the industry today. With the industry’s evolution toward more environmentally friendly vehicles, it only makes sense that JBPCO develop a new unit that can support its work truck body units within that space. Within EAVX is a research and development hub, testing artificial intelligence, robotics, lighting solutions, and more, to help us discover ways to enhance the overall value of the truck. At EAVX, we want to focus on the technical side of the chassis and body integration so that JBPCO’s body manufacturing units can focus on what they do best—building truck bodies.

HOPE: For EAVX, 2021 was all about establishing ourselves. At the end of 2020, EAVX was essentially a team of one. We grew the EAVX team to around 20 members by the end of 2021. Half of the team’s focus is electrification, and the other half is focused on the truck. But we’re still growing; I expect to have about 45 team members by the end of the year.

Last year was all about discovery for EAVX, but this year will be more focused on initial deployments and taking body designs from the drafting board paper to deployments in the field.